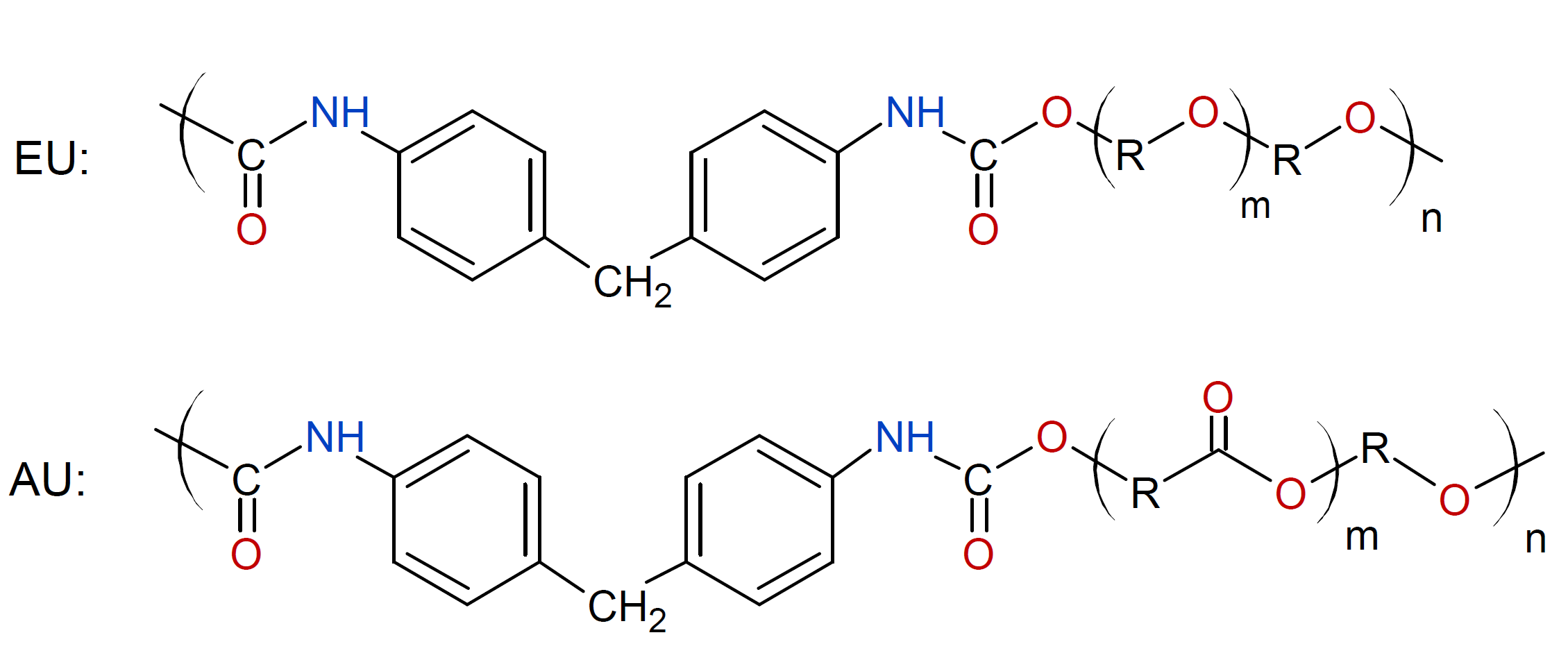

Polyurethane Elastomers (AU and EU)

Properties and Applications

Cast polyurethanes can be divided into polyester urethanes (AU) and polyether urethanes (EU). Many polyurethane elastomers are based on diphenylmethane diisocyanate (MDI). These elastomers have outstanding tensile strength, and good tear and abrasion resistance. They also have good resistance to oxidation, ozone, aliphatic solvents, and petroleum based fuels and oils. The electrical properties, the compression set and the creep properties are only fair and the heat resistance is poor.

Polyurethane elastomers are used where high abrasion resistance, high strength and good oil and solvent resistance is needed. Typical applications include hydraulic seals, gaskets, diaphragms, hoses, haul-off pads, conveyor belts, roller-skate and skateboard wheels, and many other sport good parts. They are also used for abrasion-resistant coatings and linings. In all applications, consideration should be given to hydrolysis, and limited creep and heat resistance. The typical working temperature range of AU/EU elastomers is -40°C to +90°C.